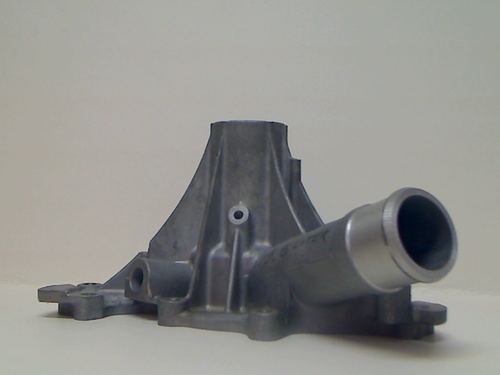

This part was used in an automotive application as part of an airbag system. It required high volume production and quality assurance that all holes were drilled in every part to its role as a safety device that saves lives.

We were invited to propose processes early on in the project. We focused on the multiple-spindle drilling operations running the length of each side of the part.

The JOST SOLUTION optimized the process by integrating multiple spindle drill heads on special horizontal CNC machining centers. The maximum number of drills possible attacked the part from opposite sides simultaneously and the material handling was similarly optimized to speed up production.

When you are looking for ideas, let’s talk!

1-800-222-9607